Indian Institute of Technology Gandhinagar (IITGN) is hosting a six-day Global Initiative of Academic Networks (GIAN) course on “Microstructural Evolution during Friction Stir Processing” from September 16 to 21, 2019. The course is being instructed by Prof Rajiv S Mishra, University Distinguished Research Professor at the University of North Texas, USA and coordinated by Prof Amit Arora of IITGN.

Faculty and students of Materials Science, Metallurgy, Mechanical, and Production Engineering from various IITs, NITs, and engineering colleges, and researchers from industry and government R&D organizations all around the nation are participating in the course.

Friction Stir Processing (FSP) is a solid-state material processing technology where the microstructure of material can be altered without melting. The process has various applications such as grain refinement, superplasticity, casting modification, low-temperature deformability, surface alloying and surface composites, etc. The process is a favorite among industries such as Boeing, Airbus, Rolls Royce, General Motors, General Electric, Apple, Hitachi, SpaceX, Bombardier, NASA, ISRO, BARC who use this technology for very specific material processing. It can be used in various primary engineering alloys like steels, aluminum alloys, titanium alloys, magnesium alloys, and alloys that cannot be traditionally processed, like immiscible copper alloys. This process is very useful for generating special property materials which can be used in automobile, space, aerospace, and naval applications.

“India is on the cusp of a major manufacturing revolution, and emerging technologies such as FSP, and High Entropy Alloys can be the push needed for the ‘Make in India’ campaign. The participants of the course can build upon the knowledge gained here, and form research clusters for future collaboration on advanced materials for advanced manufacturing technologies.”

Prof Rajiv S Mishra, University Distinguished Research Professor at the University of North Texas, USA

The course participants are learning these topics through lectures, discussion hours and lecture-demonstrations from industry practitioners. It provided the participants with an opportunity to network and interact with researchers around the country to collaborate for addressing major concerns in the field of micro-structuring.

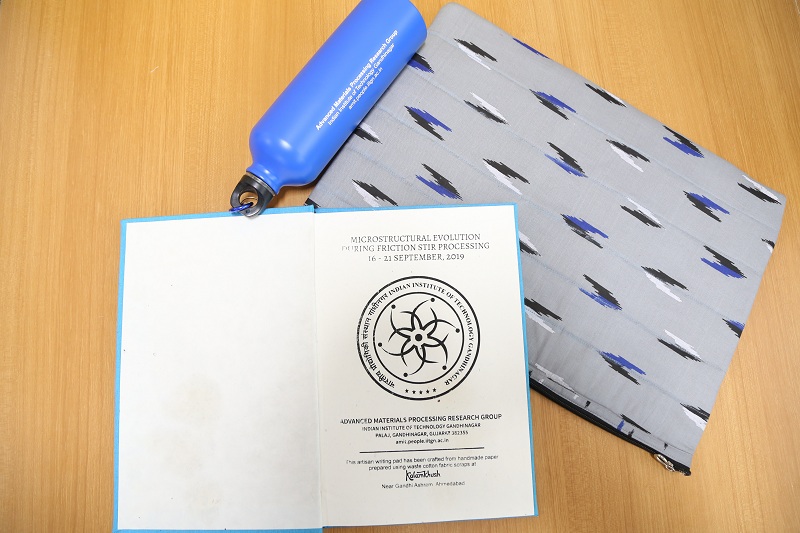

Through this course, Prof Arora and his Advanced Materials Processing Research Group decided to support sustainable livelihood generation and reducing plastic usage for this event. Course participants were provided with handmade laptop sleeves (sourced and stitched from khadi cotton by women from Palaj and Basan villages trained under IITGN’s NEEV program), a notebook of handmade paper (prepared by Kalamkhush, Khadi Gramodhyog Mandal, Ahmedabad), and reusable metallic water bottles instead of plastic ones. Course Coordinator, Prof Amit Arora said, “We at IITGN take sustainable development and environment conservation seriously in all of our activities. This initiative is our small contribution toward sustainable development and women empowerment activities at IITGN. We hope to make Swaccha Bharat, Swastha Bharat, and Kushal Bharat with every such small step.”